SBR – Wastewater Treatment Plant

The decades of operation of biological wastewater treatment plants, the resulting experience with different wastewater, a wide variety of plant engineering concepts and the evaluation of process engineering variants leads to a significantly improved understanding of biological degradation processes and as a result the development of modern and efficient treatment methods.

With the SBR process technology, a state-of-the-art process technology concept is available with which the most diverse milieu conditions can be generated in a biological treatment reactor.

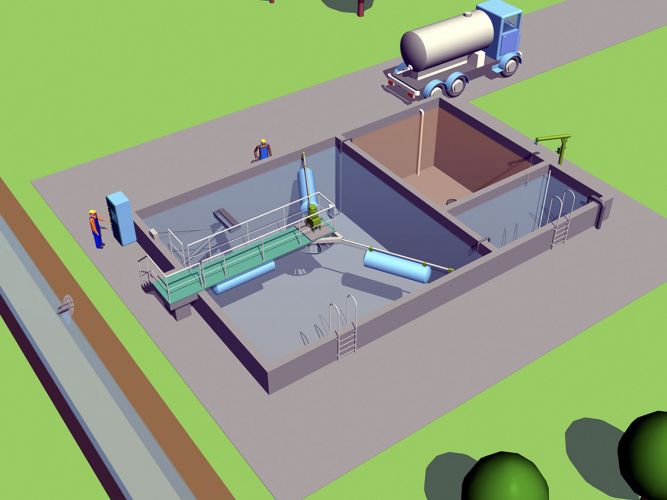

BIOGEST® manufactures biological wastewater treatment plants using the SBR (Sequencing Batch Reactor) process for wastewater treatment. Characteristic of the SBR process is the combination of the process functions “activation” and “clarification” in one reaction tank. From a procedural point of view, this results in stable and flexible processes.

Application possibilities

BIOGEST® manufactures biological wastewater treatment plants using the SBR process for wastewater treatment. Characteristic of the SBR process is the combination of the two process functions, activation and clarification, in one reaction tank. The possible applications range largely from 100 PE to 30,000 PE, but we have also implemented systems up to 400,000 PE.

Construction

The process leads to an extremely compact design and thus to a minimization of the investment costs. Thanks to the flexible system geometry (system tank with a round, square or rectangular base area), SBR sewage treatment plants from BIOGEST® can be easily implemented even under difficult installation conditions (tourist areas, leisure facilities, high-rise buildings, etc.).

Each SBR reactor combines the functions of an aeration tank and a secondary clarifier in one reactor. The construction of separate structures is not necessary and the SBR wastewater treatment plant therefore requires significantly less space.

The advantages

-

Compact design

-

Low installation costs

-

Uniformly high cleaning performance

-

Compensation for shock loads

-

Undisturbed sedimentation

-

Low sludge production

-

Optimal mixing and ventilation

-

High reliability

-

Low maintenance

BIOGEST® AG services

-

Anlagendimensionierung

-

Plant planning

-

Technical equipment

-

Installation

-

Initial operation

-

Plant optimisation during operation

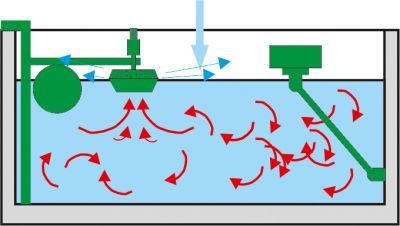

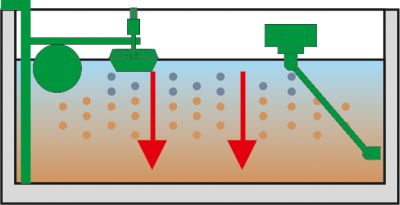

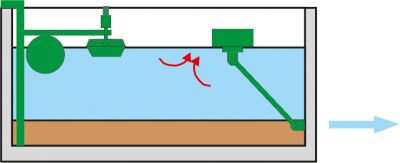

Functionality

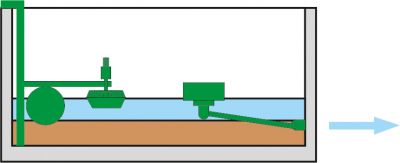

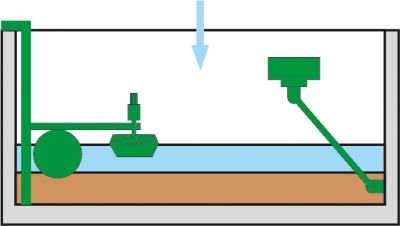

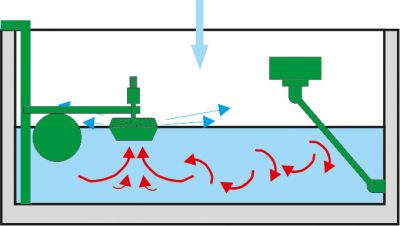

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6