Grit Trap Type GESMO

In channels where combined sewage and storm water are conveyed, there are also some coarse substances, such as grit and sewage related debris. These coarse substances usually move more slowly than the water flow and often cause problems with downstream plant and equipment. In principle the goal is to identify the sources of grit or debris entering the sewerage system and eliminate them to prevent sewage related debris within the sewer system. In reality however, debris will always be found in the sewer system. It then causes operational problems and mechanical damage to inlet or head works and pumping station equipment. The latter can be avoided, by installing grit and debris removal stations where the debris can be collected. By periodic draining and emptying smooth system operation can be maintained. This action directly affects the performance of downstream plant by significantly reducing the solids into the plant.

In conventional systems, a concrete chamber is installed in a sewer channel section to collect the grit. In this concrete chamber, aeration ducts are installed to aerate the grit. Air supply keeps the organic particles in suspension, so that they remain in the wastewater flow. Grit can be removed either with a stationary or mobile lifting device, or by means of vacuum suction vehicles. The grit removal is usually executed during operation, i.e. when the grit trap sewer is flooded. In this case there is a danger of damaging equipment or the civil structure with the lifting system. If the removal is carried out by suction vehicles, the inlet into the structure must be closed.

The BIOGEST® Grit Trap Type GESMO allows you to trap grit and debris from sewer networks in combined sewage-storm water and rainwater systems.

Selective retention and removal of debris and grit from channels

Functionality

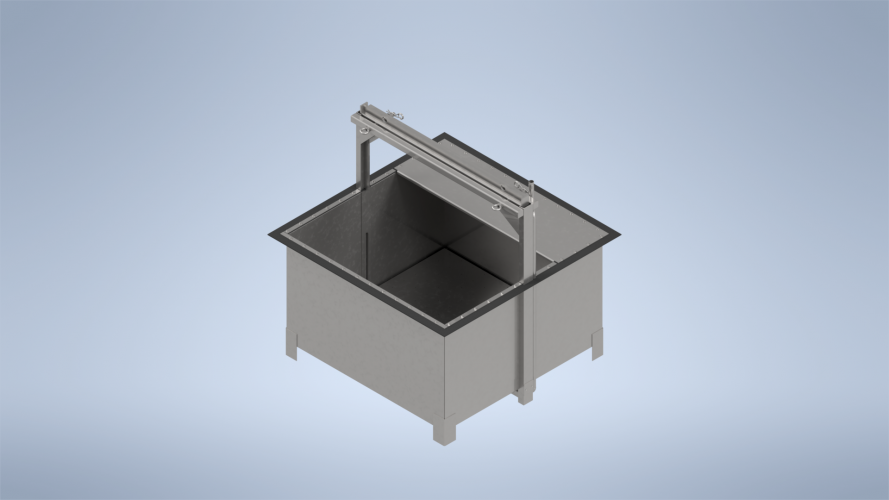

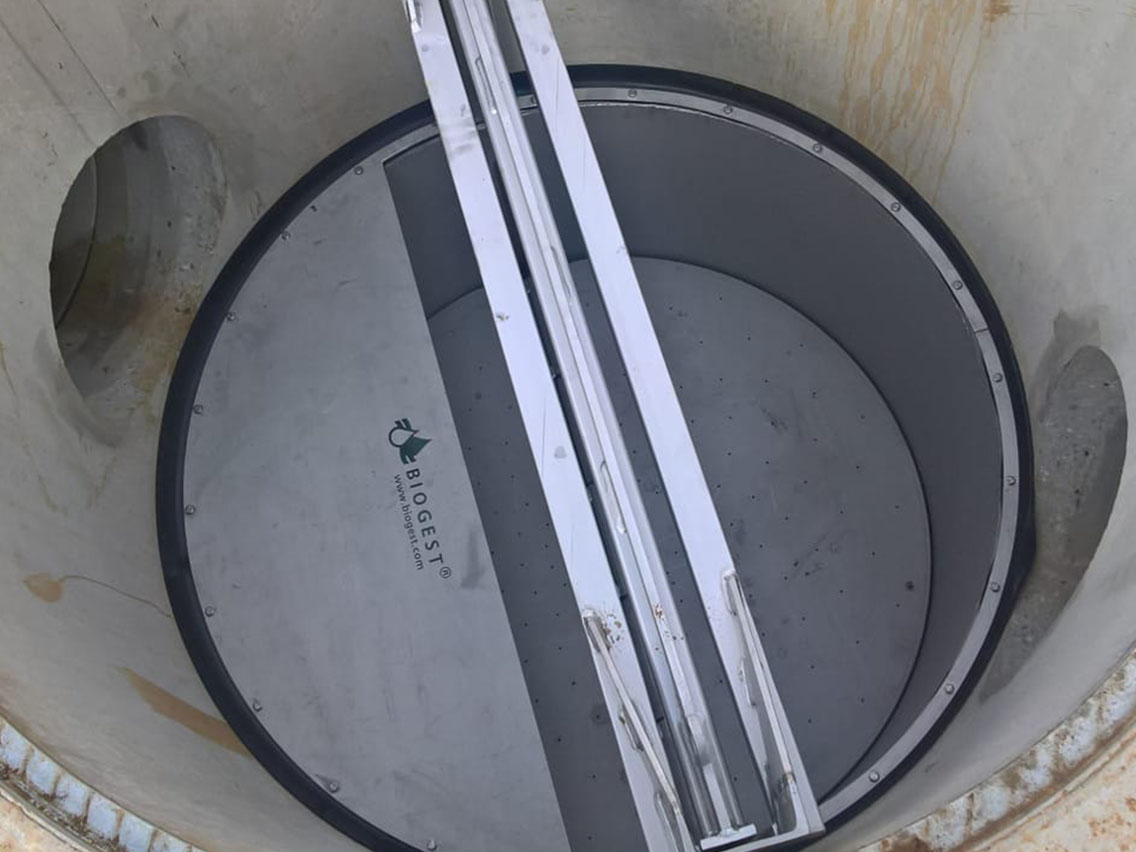

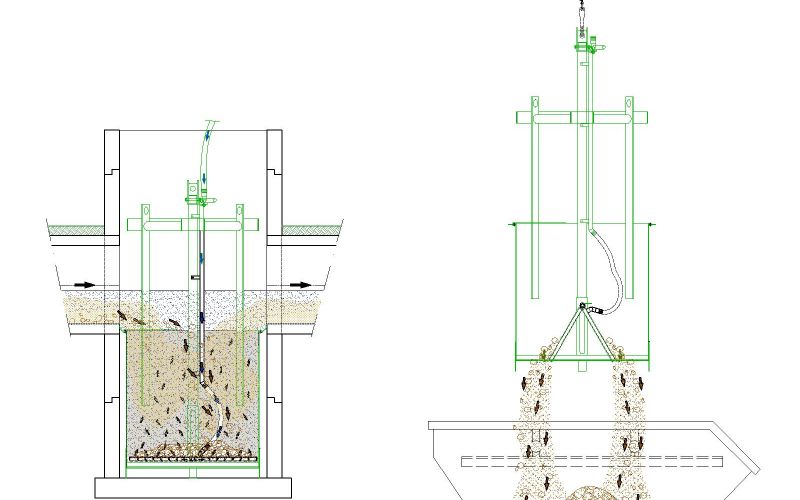

The grit trap basket is positioned in a specially designed sump by means of lifting tackle. A rubber lip is attached to the outer edge of the trapping basket to seal the clearance between the basket and the sump wall. At the same time, this lip allows easy locating of the trapping basket within the sump. An inlet plate reduces the residence time in the sump area and therefore minimises the sedimentation of light materials. The bottom of the basket is provided with holes that are pressurized by air to ensure good aeration and recirculation of the debris.

Installation and commissioning in the sewer can be achieved quickly by interrupting the flow briefly whilst the sump is emptied. Thereafter the grit trap basket is lowered in the sump, connected and is ready for service.

To empty the trap basket, uncouple the pressure hose and lift the basket out of the sump completely, using a lifting mechanism. Grit and debris will remain in the basket. The residual water will drain out through the bottom of the trap basket. Empty the basket into a dumpster of sip or alternatively directly into the waste vehicle. To open the grids, fold them by pulling the unlocking rod in the centre. The debris will slide out from the retaining surfaces in the base. After emptying the basket, swivel the grids back and return the basket back into the sump. After reattaching the pair pressure coupling the grit trap is ready for use.

The advantages

- Easy collection and removal of grit and debris

- Fast emptying of the grit trap during running operation

- No technical installations in the grit trap chamber required

- Simple low-cost installation

- Low maintenance

- Compact and robust design in stainless steel

- Available without aeration